Enclosures

Joint Enclosures

An underground fibre enclosure is a rugged, weatherproof box, typically made of UV-resistant plastic, that safeguards fibre optic cable connections and terminations buried beneath the ground. These enclosures keep out moisture with watertight seals, provide multiple entry ports for secure cable management, and often include splice trays for internal organization. They are also lockable for security and offer easy access for technicians to perform installation, maintenance, or troubleshooting, ensuring the smooth operation of underground fibre optic networks.

FOBOT Enclosures

Below left we have a wall mount fibre tray called a FOBOT (Fibre Optic Break Out Tray) to the right is a sliding Fibre tray designed to be mounted in a communications rack (usually at the top of the rack)

Fibre Jacket types

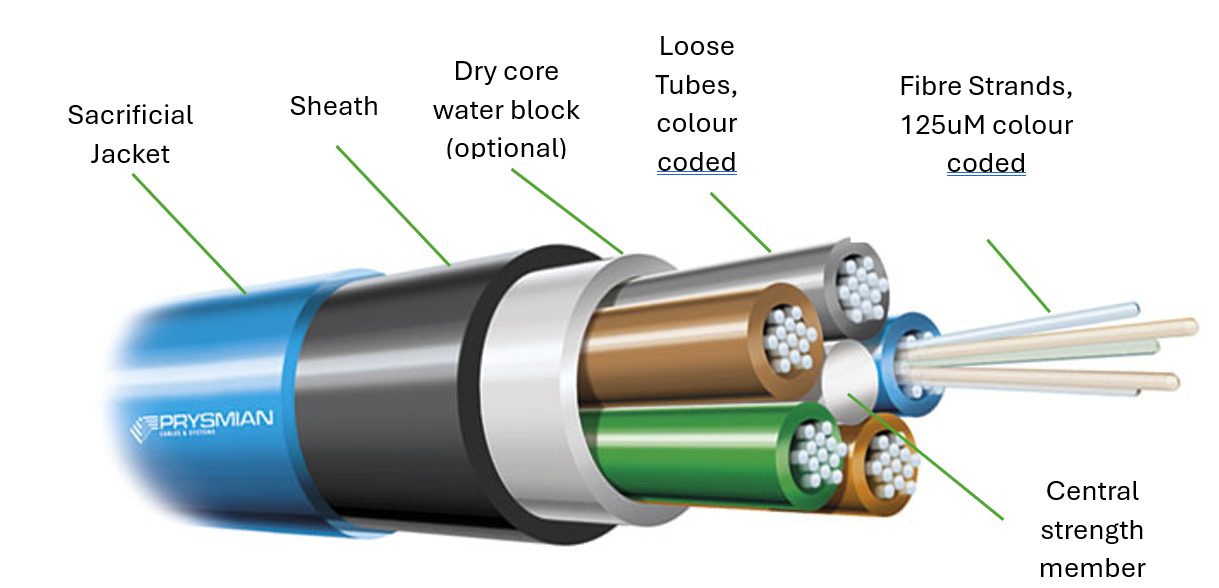

Loose Tube

Loose tube fiber optic cable is the most common fibre cable installed, it has excellent durability for underground applications, the central strength member creates a ridgid fibre that requires large bend radius in pit and pipe work with a general minimum of 50mm conduits and sweeps not bends or elbows for the pathways. When run internally in buildings it is best to encase the fibre in conduit to prevent dangerous gasses in the event of a fire.

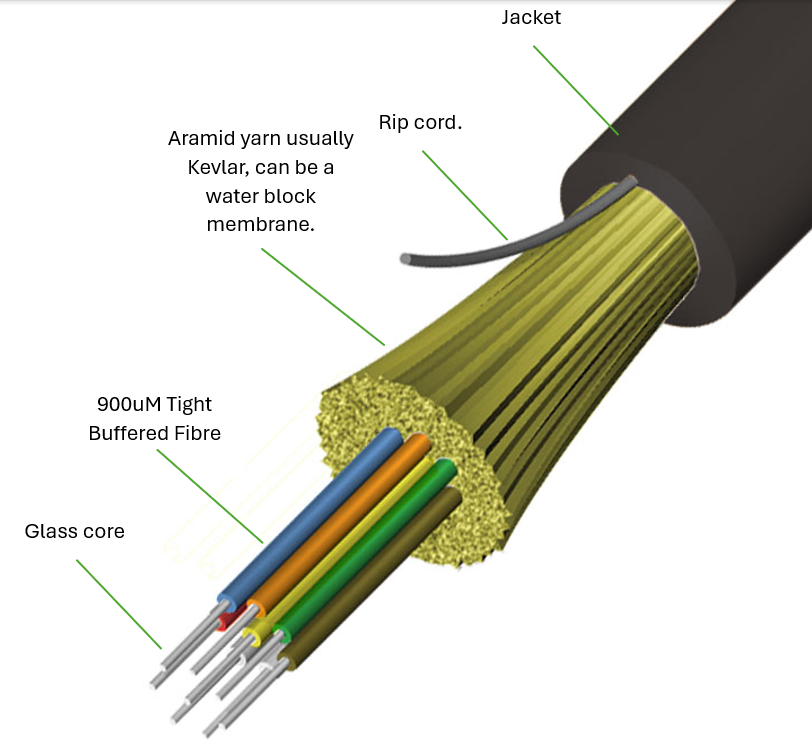

Indoor / Outdoor riser fibre

Indoor outdoor riser fibre is primarily designed for applications inside of buildings but can in some circumstances be used outdoors when it is not possible or desirable to use Loose Tube. The main benefits of this fibre are it's flexibility as there is not central strength member, it is possible to mistake this for a normal Cat 6 Data Cable. The fibre strands are physically larger at 900um compared to the 125um of loose tube. This can make termination fast and cable prep quicker as the fibre is not as difficult to break into, there is also no messy gel.